The tablet formulation of SoChlor reduces the need for transportation of water, creating lighter, more compact packages which create less CO2 during delivery. Further positives come from using SoChlor solutions with a microfibre or reusable cloth, reducing the volume of disposable wipes and waste.

New Technologies We Use:

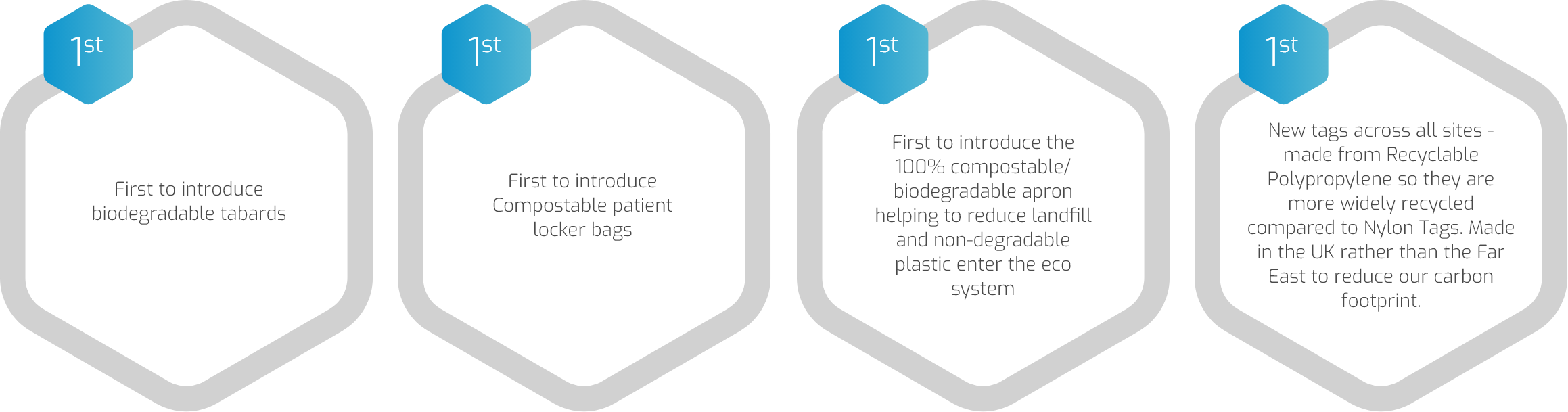

Oxo-Biodegradable Plastic Technology

Supporting the globally recognised ambition of ‘Reduce, Reuse and Recycle’, oxo-biodegradable plastic technology is used for our Biodegradable Aprons. At the end of the plastic’s functional life cycle, it is broken down in the presence of oxygen. This converts into materials with a low molecular weight and which are no longer plastics, and are completely biodegradable.

Oxo-Biodegradable Plastic does not fragment into microplastics and will be recycled back into the environment through biodegradation by naturally-occurring bacteria and fungi.